Industrial Excellence

Delivering top-tier products and services with a focus on operational excellence and reliability for every client.

Reliable Delivery

On-time, secure, and efficient delivery of industrial materials and solutions across Saudi Arabia and beyond.

Quality Assurance

Stringent quality control and certified testing ensure every product and service meets the highest standards.

About Us

We're more than just a provider of industrial materials and non-destructive testing (NDT) services - we're your dedicated partner in ensuring operational excellence and structural integrity. We leverage deep industrial expertise to deliver high-quality solutions that meet the rigorous demands of various sectors, including oil and gas, petrochemical construction and power generation.

Our Mission

Our mission at Zafer Kabeer Ahmed Trading & Contracting Est., is to empower industries in the kingdom and beyond with reliable industrial materials and precise non-destructive testing (NDT) solutions. We are committed to being your trusted partner, ensuring the integrity, safety and efficiency of your operations.

Our Values

Our operations in industrial materials trading and non-destructive testing are guided by a core set of values - Integrity, Excellence, Safety, Reliability, Client focus. These principles define who we are , how we operate, and our unwavering commitment to our clients and the industries we serve.

Why Choose Us?

- ✓ Extensive product inventory

- ✓ Competitive pricing

- ✓ Quality guaranteed products

- ✓ Client-centric solutions

- ✓ Experienced and Certified Professionals and Technicians

Industrial Pipes

High-quality steel, stainless steel, and alloy pipes for various industrial applications

Our comprehensive range of industrial pipes includes carbon steel, stainless steel, and specialty alloy pipes designed for demanding industrial environments. Each pipe undergoes rigorous quality testing to ensure optimal performance and longevity.

Available Specifications

- Carbon Steel: A53, A106, A333, API5L

- Stainless Steel: A312, A358

- Types: ERW and Seamless available

Pipe Fittings

Comprehensive range of pipe fittings for secure and reliable connections

Our extensive collection of pipe fittings includes elbows, tees, reducers, couplings, and specialized fittings. All fittings are manufactured to international standards ensuring perfect compatibility and long-lasting performance.

Available Specifications

- Carbon Steel: A234 WPB, A420 WPL6

- Stainless Steel: A182-304/304L/316/316L, A312 TP-304/304L/316/316L

Industrial Flanges

Precision-engineered flanges for critical industrial applications

Our flange collection encompasses all standard types including slip-on, weld neck, blind, and specialty flanges. Each flange is precision-machined and tested to ensure perfect sealing and structural integrity in high-pressure applications.

Available Specifications

- Materials: Carbon steel, Stainless steel

- Size: ½” to 48”

- Class: 150, 300, 600, 900

- Types: Slip-on, Weld neck, Threaded, Socket weld, Blind, Ring joint, Lap joint

Industrial Valves

Reliable flow control solutions for demanding industrial environments

Our valve portfolio includes gate valves, ball valves, check valves, butterfly valves, and specialized control valves. Each valve is designed for optimal flow control, durability, and safety in critical industrial processes.

Available Specifications

- Materials: Carbon steel, Stainless steel

- Size: ½” to 24”

- Class: 150, 300, 600, 1500

- Types: Ball valve, Gate valve, Check valve, Globe valve, Butterfly valve

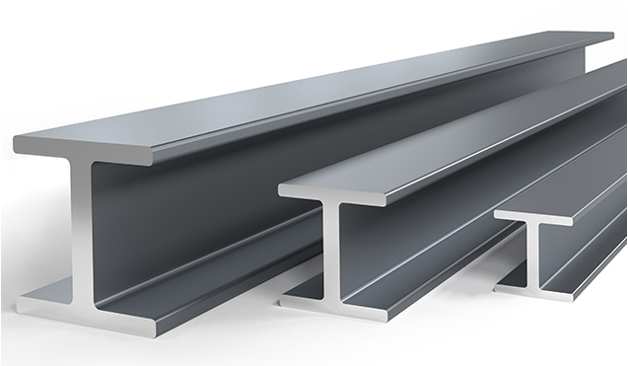

Steel Structures

Structural steel components and fabricated structures for industrial construction

We provide comprehensive structural steel solutions including beams, columns, trusses, and custom fabricated structures. Our structural components are designed to meet the highest safety standards and engineering requirements.

Available Specifications

- I Beam, H Beam

- U Channel, C Channel

- Gratings

- Sheets, Plates

Gaskets & Fasteners

High-quality gaskets and fasteners for industrial applications

We supply a wide range of industrial gaskets and fasteners designed for secure, leak-proof, and durable connections in piping and structural systems. Our products meet international standards and are suitable for a variety of demanding environments.

Available Specifications

- Gaskets: Ring joint, Spiral wound, Synthetic rubber, Teflon, PTFE

- Fasteners: Nuts & washers, Stud bolts, Anchor bolts, Machine bolts

Contact Us

Get in touch with us for inquiries, quotes, or support

Remote Visual Inspection (RVI) (Boroscopy)

Advanced internal inspection using boroscopy for inaccessible areas.

Remote Visual Inspection (Videoscopy) enables the examination of areas or components that are difficult to access with the naked eye, without the need to dismantle machinery or surrounding structures. This technique helps detect discontinuities such as surface defects, substandard welds, pitting, corrosion, wear, blockages, and foreign objects—allowing early identification and prevention of potential issues before they escalate into major problems.

Hardness Testing (HT)

On-site and laboratory hardness testing for metals and alloys.

The Ultrasonic Contact Impedance (UCI) method offers a highly efficient and largely non-destructive way to measure material hardness, particulary valuable for finished components and in-situ inspections. Hardness testing is available by MIC 10 and Telebrineller system .The UCI method provides a reliable and practical solution for quality control, material verification and asset integrity management, ensuring that critical components meet required hardness specifications.

Thermography

Infrared thermal imaging for preventive maintenance and diagnostics.

Thermography is a technique used to inspect electrical and mechanical equipment by capturing images of heat distribution. It is based on the principle that malfunctioning components typically exhibit a rise in temperature. In electrical systems, this could result from loose connections, while in mechanical systems, it may indicate issues like worn bearings. By analyzing the thermal patterns of components during operation, potential faults can be identified and assessed for severity.

Positive Material Identification (PMI)

On-site alloy verification and chemical analysis for quality assurance.

It is well known that even a small mix-up in materials can lead to serious accidents and significant financial losses. To prevent such incidents, quality-conscious project managers are increasingly implementing Positive Material Identification (PMI) at every stage of plant commissioning. Material mix-ups can occur at various points—during manufacturing by the vendor, during storage by the user, or during the fabrication process. By conducting PMI at each of these stages, organizations can ensure near 100% confidence in preventing material identification errors.

Holiday Testing (Spark Test)

Detection of coating defects using high-voltage spark testing.

A holiday test is a non-destructive inspection method used to detect discontinuities in painted or coated surfaces using specialized equipment. These devices, known as holiday detectors, are portable tools that are moved across the coated surface to identify any flaws. The test operates on the principle of electrical conductivity. Metal substrates are excellent conductors of electricity, allowing current to pass through them easily, while most coatings are poor conductors and resist electrical flow. Based on this difference, holiday testing uses electrical instruments to locate imperfections such as pinholes or thin spots in anticorrosive paints and coatings.